Very Narrow Aisle (VNA) Racking Optimisation

An international ingredients supplier looking to build on their successful distribution operation in the UK and Europe turned to Teccon for help and advice in the design and installation of racking and safety systems into a new purpose built warehouse.

Chosen after a competitive tender, we demonstrated from the start a comprehensive yet consultative approach to the project with rapidly changing goals to create a single cohesive solution to maximise storage and efficiency.

Challenge

Engaged at the early design phase, before the warehouse was built, we were to consider and implement designs to maximise storage and efficiency, consulting on the optimum solution from the concrete slab to the size of structure.

Being in control of these variables and pulling on our experience, we were to mitigate any potential issues such as accessibility from low access points as well as maximising the full usage of the warehouse.

Additionally the inclusion of safety systems was a core feature of our remit to provide a safe working environment and to reduce the risks inherent with VNA racking systems.

Solution

The ability to calculate the maximum load weight of the in place concrete base allowed us to specify the optimum size of the warehouse to accomplish their necessary enhanced capacity goals.

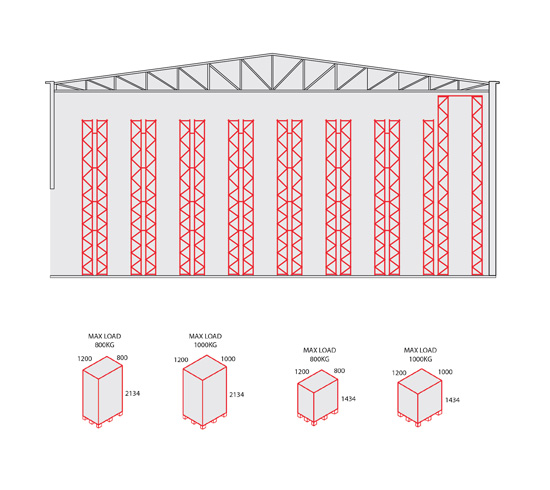

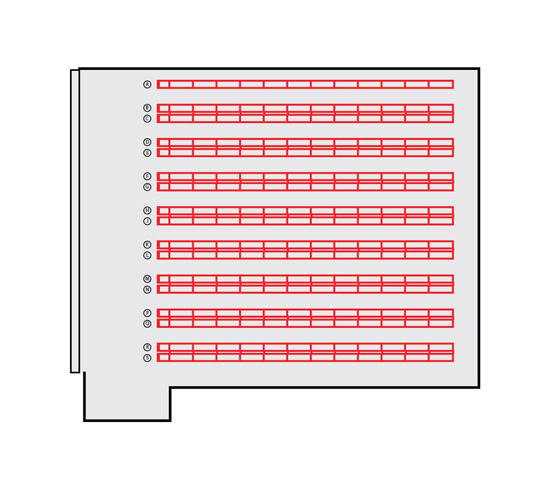

With these parameters available and the client's enthusiasm for VNA (Very Narrow Aisle) racking we specified and installed 3300 Pallet Racking positions up to 15m in height for maximum storage and to optimise the efficiency we specified P&D Beams (Pickup and Deposit) to assist in load handling between trucks.

For safety during use we introduced wire guidance for the VNA trucks and as an overall safety measure against fire, an option only available from the early planning stages In-rack and Roof Sprinklers were added to protect the warehouse, it's contents and the teams within.

In line with the customer's long term goals, the increased volume of pallets available and seamlessly integrated warehouse will enable the expansion of their operations in the UK and Europe.

Delivering consistent quality throughout, our proven systems, client communication and dedication to client operational needs demonstrate exactly why Teccon continue to receive the customer confidence needed to be the first choice for storage solutions and expansion projects such as this.

Specifications

8 Beam Levels per bay complete with Pallet Support Bars

P&D beams (Pickup and Deposit Stations) are added to assist in load handling between trucks

In-Rack Sprinklers

Roof Sprinklers